Home > products > Valve > Automatic Control Valves

Features

Non-Surge Check Valve closes automatically in case of prevent mediums back-flow.

The Non-Surge Check Valve allows flow when inlet pressure in higher than the outlet pressure.

The valve has the principal of slow-open, quick-close and slow-close into one to prevent water hammering when the pump starts or closes.

Non-Surge Check Valve opens and closes at controlled speed to ensure smooth flow.

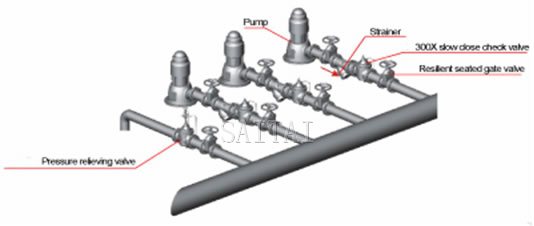

Used on the pump outlet of a water supply system to prevent mediums back-flow, water hammer and water shock. It has three functions as an electric valve, check valve and water hammer remover. It is capable of improving the safety and reliability of the water supply system effectively through integrating the technical principle of slow-open, speed valve, slow-close, and removing water hammer and preventing of both pump-starting and pump-stopping water hammer. The gate can carry out open-close automatically upon the operation rules of the water pump just by operating the pump to open or close electrically. Hydraulic Check Valves features by the big flow and small pressure loss, reliable sealing performance, easy installation, debugging and maintenance and long duration.

Supplier: Saitai Valve, China

Manufacturer: Shop in Shanghai Qingpu Industrial Park

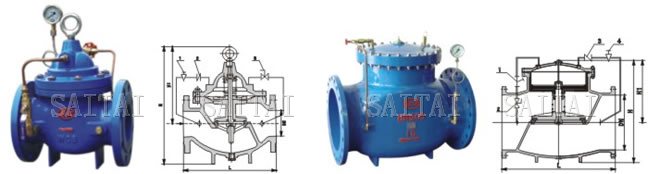

DN 450 Diaphragm type valve

DN 500 piston type valve

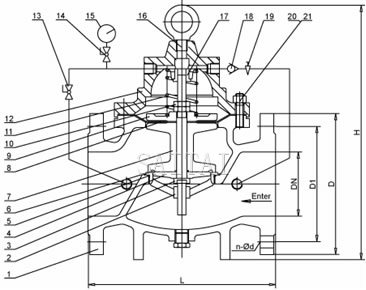

Notes:

1. Needle Valve

2. Check Valve

3. Small Ball Valve

Technical Parameters

Nominal Pressure: 1.0, 1.6, 2.5MPa

Shell test pressure: 1.5, 2.4, 3.75MPa

Sealed test pressure : 1.1, 1.76, 2.75MPa

Suitable temperature: 80

Suitable medium: water, Sewage

Materials

| Serial No. | Part | Material |

| 1 | Body | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 2 | Seat | 2Cr13 / SS 304 / SS 316 |

| 3 | Stem | 2Cr13 / SS 304 / SS 316 |

| 4 | O-ring washer | Cast Iron |

| 5 | O-ring | NBR |

| 6 | O-ring | NBR |

| 7 | Disc | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 8 | Diaphragm | Rubber |

| 9 | Diaphragm washer | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 10 | Nut | Bronze |

| 11 | Spring | Spring steel |

| 12 | Cover | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 13 | Ball valve | Bronze |

| 14 | Ball valve | Bronze |

| 15 | Pressure show | |

| 16 | Hang ring | Steel |

| 17 | Pilot socket | Pilot socket |

| 18 | Single way valve | Bronze |

| 19 | Needle valve | Bronze |

| 20 | Stud | Steel |

| 21 | Nut | Steel |

Dimensions

| DNmm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | |

| L | 180 | 180 | 180 | 203 | 203 | 235 | 285 | 360 | 400 | 455 | 585 | 650 | 800 | 860 | 915 | 980 | 1075 | 1230 | 1300 | 1450 | |

| PN10 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 390 | 440 | 500 | 565 | 615 | 670 | 780 | 895 | 1010 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | |

| PN16 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 460 | 520 | 580 | 640 | 705 | 840 | 910 | 1020 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | |

| PN25 | D | 105 | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 | 955 | 1070 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | 875 | 990 | |

| H | 172 | 172 | 172 | 265 | 265 | 310 | 350 | 460 | 520 | 570 | 695 | 780 | 905 | 1025 | 1080 | 1030 | 1135 | 1270 | 1460 | 1640 | |

| H1 | 106 | 106 | 106 | 210 | 210 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 658 | 696 | 735 | 610 | 665 | 725 | 865 | 925 | |

Typical Installation

Non-Surge Check Valves Related Products

Next:Rate-of-Flow Control Valves

Catalog:Automatic Control Valves

Above:Pressure Reducing Control Valves